-

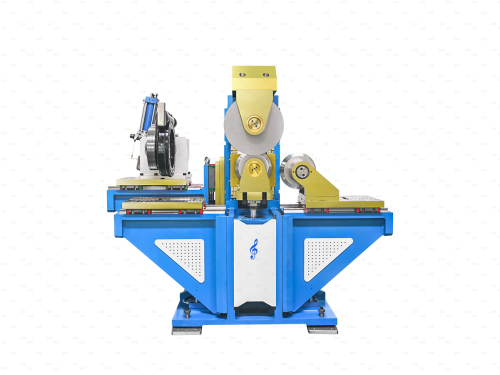

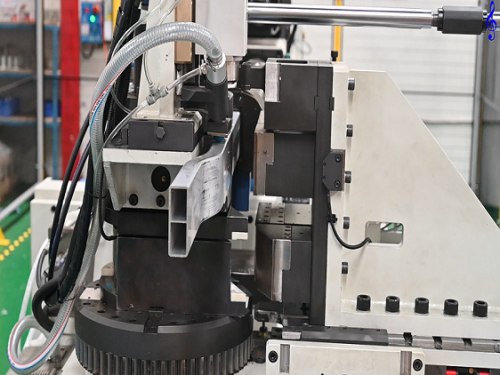

Vertical roll bending machine A12T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. The 4th roller can be customized based on your needs. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. As our mature product, the sample-making period and lead time are short to satisfy your urgent needs. Profile max cross-section area: 60*60*3mm. Min. bending radius: section height* 5-8.

Vertical roll bending machine A12T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. The 4th roller can be customized based on your needs. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. As our mature product, the sample-making period and lead time are short to satisfy your urgent needs. Profile max cross-section area: 60*60*3mm. Min. bending radius: section height* 5-8. -

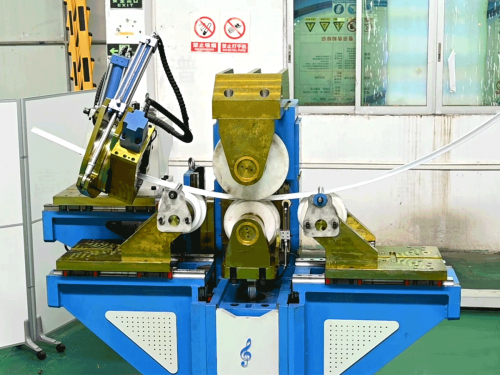

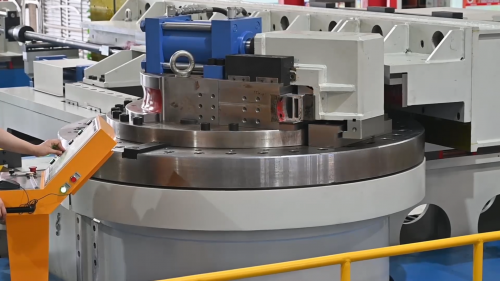

G-Clef vertical CNC roll bending machine A30T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D /3D bending is optional. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8.

G-Clef vertical CNC roll bending machine A30T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D /3D bending is optional. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8. -

G-Clef CNC Y08T roll bending machine can be used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, doors and windows, curtain walls, bathroom hardware and gym equipment and other industries. It can process iso-distance spiral, mosquito coil arc and rolling shutter door guide rail and other complex arcs with high precision.

G-Clef CNC Y08T roll bending machine can be used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, doors and windows, curtain walls, bathroom hardware and gym equipment and other industries. It can process iso-distance spiral, mosquito coil arc and rolling shutter door guide rail and other complex arcs with high precision. -

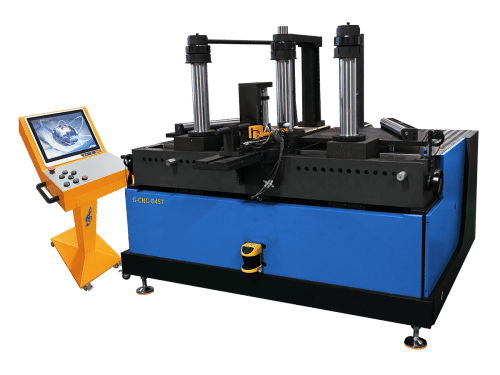

G Clef Roll Bending Machine G-CNC-S10T is able to bend tubes and profiles in both directions of LH/RH, which can satisfy your needs of complex-shape bending. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost.

G Clef Roll Bending Machine G-CNC-S10T is able to bend tubes and profiles in both directions of LH/RH, which can satisfy your needs of complex-shape bending. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. -

Horizontal roll bending machine B20T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. The 4th roller can be customized based on your needs. With the CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. As our mature product, the sample-making period and lead time are short to satisfy your urgent need. Profile max cross-section area: 80*80*3mm. Min. bending radius: section height* 5-8.

Horizontal roll bending machine B20T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. The 4th roller can be customized based on your needs. With the CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. As our mature product, the sample-making period and lead time are short to satisfy your urgent need. Profile max cross-section area: 80*80*3mm. Min. bending radius: section height* 5-8. -

G-Clef horizontal CNC roll bending machine B30T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D or 3D bending function is available. With the CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8.

G-Clef horizontal CNC roll bending machine B30T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D or 3D bending function is available. With the CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8. -

Horizontal roll bending machine B45T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. With the CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost.

Profile max cross-section area: 150*100*3mm. Min. bending radius: section height* 5-8. -

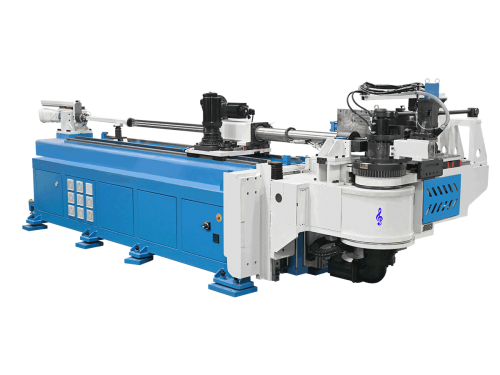

Equipped with a CNC system, G Clef tube bending machine has bending capabilities of multi-radius, multi-angle, and multi-direction. Adopting original eccentric bending technology, it can realize small radius bending. Moreover, there is no need of manual correction after bending. It can be adapted to a wide range of machines (robot grippers, drilling devices, etc.), and realize automated production.

Equipped with a CNC system, G Clef tube bending machine has bending capabilities of multi-radius, multi-angle, and multi-direction. Adopting original eccentric bending technology, it can realize small radius bending. Moreover, there is no need of manual correction after bending. It can be adapted to a wide range of machines (robot grippers, drilling devices, etc.), and realize automated production. -

This machine A210D can bend 210×12mm steel pipe, suitable for medical equipment and other industries. Equipped with a CNC system, G Clef tube bending machine has bending capabilities of multi-radius, multi-angle, and multi-direction. Adopting original eccentric bending technology, it can realize small radius bending. Moreover, there is no need of manual correction after bending. It can be adapted to a wide range of machines (robot grippers, drilling devices, etc.), and realize automated production.

This machine A210D can bend 210×12mm steel pipe, suitable for medical equipment and other industries. Equipped with a CNC system, G Clef tube bending machine has bending capabilities of multi-radius, multi-angle, and multi-direction. Adopting original eccentric bending technology, it can realize small radius bending. Moreover, there is no need of manual correction after bending. It can be adapted to a wide range of machines (robot grippers, drilling devices, etc.), and realize automated production. -

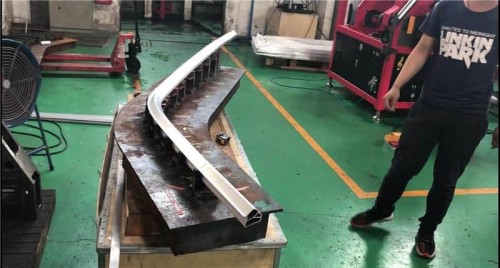

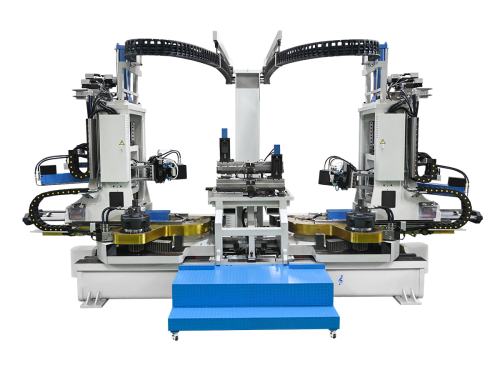

3D Stretch Bending Machine can satisfy your needs of multi-direction bending, with optional stretch power ranging from 2 tons to 35 tons. With the technology of stress neutral layer control and spring-back control, G Clef stretch bending machine is able to avoid wrinkles, fractures and other problems, and ensure the bending quality. The positioning accuracy reaches 0.03mm, enabling the qualification rate of this machine to reach over 99%.

3D Stretch Bending Machine can satisfy your needs of multi-direction bending, with optional stretch power ranging from 2 tons to 35 tons. With the technology of stress neutral layer control and spring-back control, G Clef stretch bending machine is able to avoid wrinkles, fractures and other problems, and ensure the bending quality. The positioning accuracy reaches 0.03mm, enabling the qualification rate of this machine to reach over 99%.