The calculation of elongation

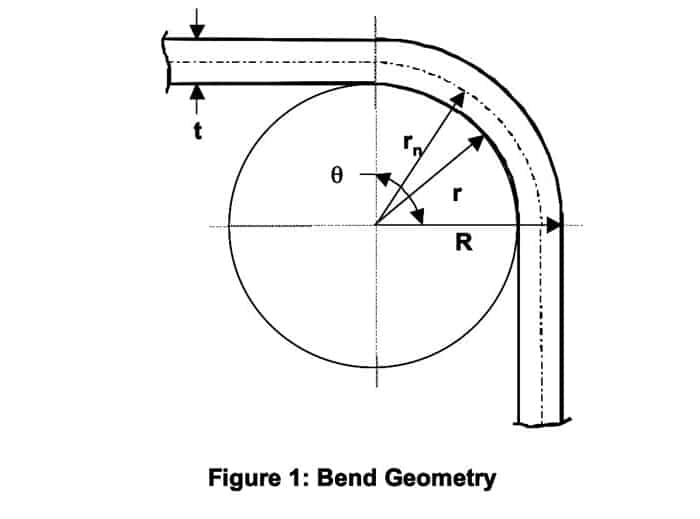

T (sheet thickness) = r (outside) – r (inside)

ð (elongation rate) = t / r (inside) ×100%

The national production standard for Aluminum profile(6063、T5)is ð (elongation rate) ≥ 8 %

The general elongation rate requirements in Aluminum profile stretching

Aluminum profile(6063, T5): When the bending ð (elongation rate) ≤ 10 %, the aluminum profile for general purpose is available.

B. Aluminum profile(6063, T5): When the bending ð (elongation rate) ≥ 10 %, if the profile sheet thickness is relatively big, cavity is enclosed, geometry is comparatively simple, force in bending direction is symmetrical, width-height ratio is less than 1, generally the elongation rate in bending can reach the range of 10% to 16%.

C. If the profile bending is beyond the above condition, we should consider the other aluminum profile hardness, for example T0 ~ T4. Generally speaking, under the T0 condition Aluminum profile (6063) elongation rate can reach 20% ~ 28% .

D. In a word, the requirement in profile bending elongation should be based on the specific design and material selection ( geometry, sheet thickness, cavity enclosed rate, force symmetry in bending direction, tensile strength, and so on ) .

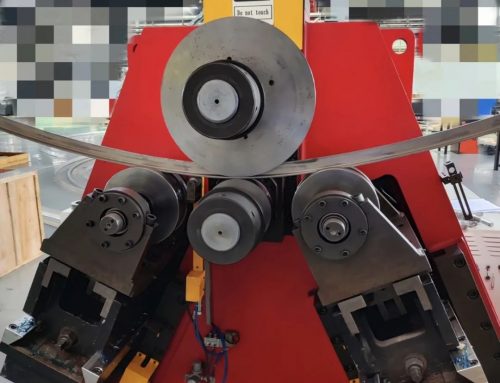

We’re the metal profile stretch forming machine and roller bending machine manufacturer, if you have any advices and suggestions please contact us immediately.

评论