What is Stretch Forming Machine?

Stretch forming machine is a type of metalworking equipment most commonly used in automobile manufacturing, aerospace and other high-precision bending processing applications. During the stretch forming, or wrap forming process, metal sheets or extrusions are stretched to exceed their inherent elastic limit and formed around contoured dies to create the desired shape. This “stretching” process results in an increased material yield strength and a stronger finished part. Since stretch forming machines maintain constant tension of the metal throughout the process, they minimize imperfections and wrinkles.

This process can produce parts of varying complexity, from a simple curved part such as an aircraft skin, car bumper to one with intricate geometries consisting of non-uniform cross sections. Most leading edge parts, joined structural sections, and contoured trim are created using stretch forming machines.

Types of Stretch Forming Machine

G Clef designs and builds machines for three main types of stretch forming: sheet (transverse) , extrusion (transverse) and 3D.

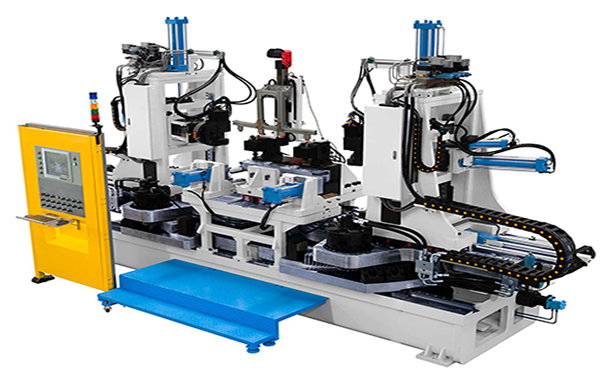

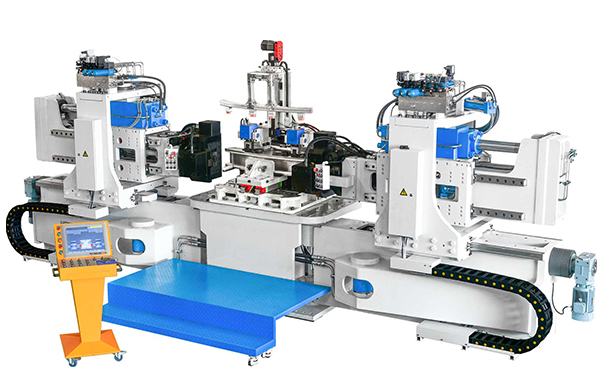

3D Stretch Forming

3D Stretch Forming is the most advanced stretch former in G Clef.In 3D stretch forming, the metal (blanks) are clamped between gripping jaws which are attached to movable arms. The 3D die is mounted to a die table attached to the machine. During the product process, the movable arms can move up and down,forward and backup. And the arms engage (either independently or simultaneously) to wrap the blank around the 3D die. The resulting extrusions are used primarily in the aerospace industry,automotive industry, for high-precision structural parts. See an 3D Stretch Forming Machine on YouTube:Multifunctional 3D stretch forming machine

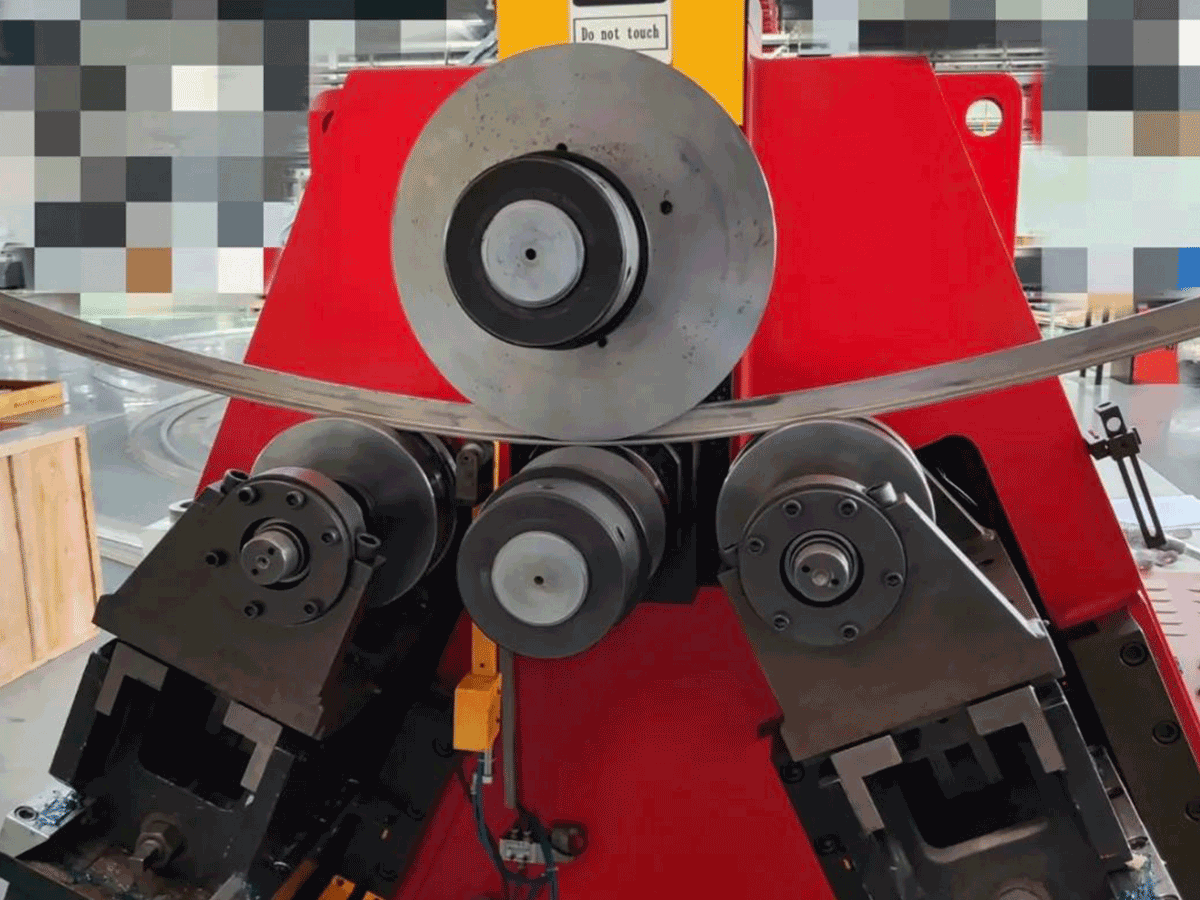

Sheet Stretch Forming Machine

In sheet stretch forming, a large sheet metal blank is placed atop the die or stretch form block. The blank is held in place by gripping jaws which hold the edges of the sheet metal. During the cycle, the stretch form block (die) moves upward and pushes against the sheet until it forms into a contoured shape. Features like oscillating carriages enable the machine to form a variety of complex bends and angles in one cycle. Sheet stretch forming machines are most commonly used to form large metal panels for the aerospace and transportation industries. See a Sheet Stretch Forming Machine on YouTube:Car bumper production-Stretch forming machine

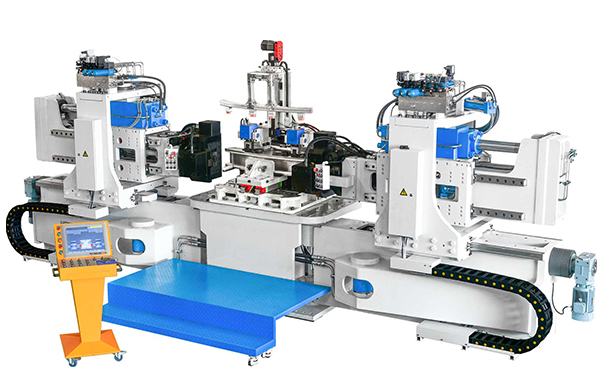

Extrusion Stretch Forming Machine

In extrusion stretch forming, long pieces of metal (blanks) are clamped between circular gripping jaws which are attached to movable arms. The contoured die is mounted to a die table attached to the machine. During the cycle, the arms engage (either independently or simultaneously) to wrap the blank around the contoured die. The resulting extrusions are used primarily in the aerospace industry for wing stringers, chords, and other structural parts. See an Extrusion Stretch Forming Machine on YouTube:push stype stretch forming machine

Features of G Clef’s Stretch Forming Machines

1,Beyond 16-axis servo control, stretch force and displacement are accurate.

2, Force mode or displacement mode are available in bending.

3, Automatic detection of profile yield strength, and stretch force adjusting accordingly.

4, Self-study CNC program, automatic molding parameter generation.

5, Stable bending quality and consistent bending accuracy.

6, Independent of skilled operator.

7, Energy-saving and green solution is provided to solve the hydraulic system’s heating problem.

Quality first, innovation last, creation always in everything we do. We are keeping to exceed by continued!

Why are Stretch Formers the Best in the Industry?

Our stretch forming machines are engineered for Infinite Life using Finite Element Analysis (FEA) software and feature high-quality, standard components from the best suppliers in the industry. Additionally, G Clef is an partner of KIRCHHOFF, COSMA, BMW, TESLA, FORD, TOYOTA, HONDA, Such as famous enterprises, as well as numerous automobile manufacturers.Automatic bumper bending system onYouTube.

Leave A Comment