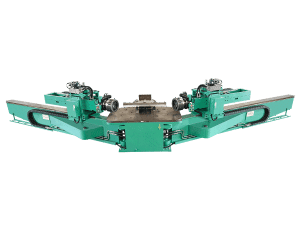

The hydraulic system of G Clef adopts advanced servo technology. The roller shafts and rocker arms are independently controllable, with stepless speed regulation and automatic pressure adjustment. This ensures the quality and consistency of cold-formed profiles and can provide stable, high-precision, and low-cost domestic bending equipment for escalator enterprises.

Core Competence

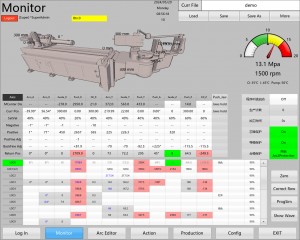

Repeated stable operation

The repeated positioning accuracy of the roller shafts of the CNC roll bending machine is less than 0.01mm.

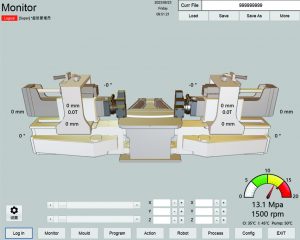

Precise servo control

More than 16-axis servo control for accurate and real-time control of stretching force and displacement.

Unique eccentric tooling design

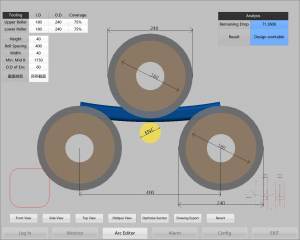

The same layer of tooling can have multiple radii, with a maximum of up to R5000.

Leave A Comment