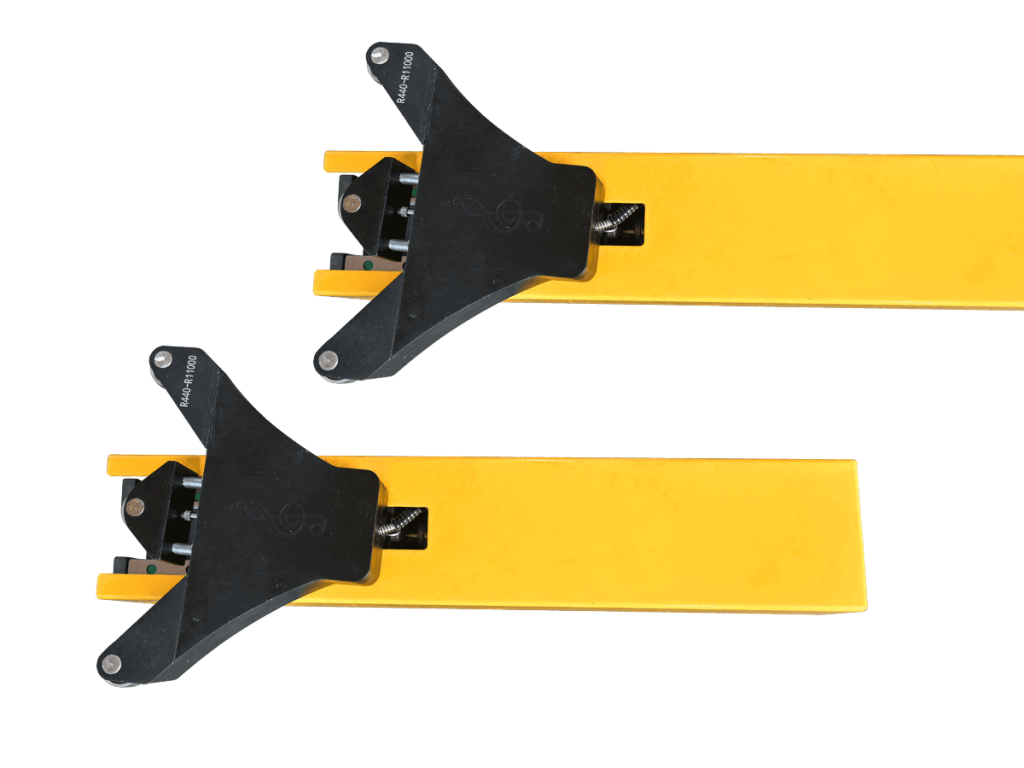

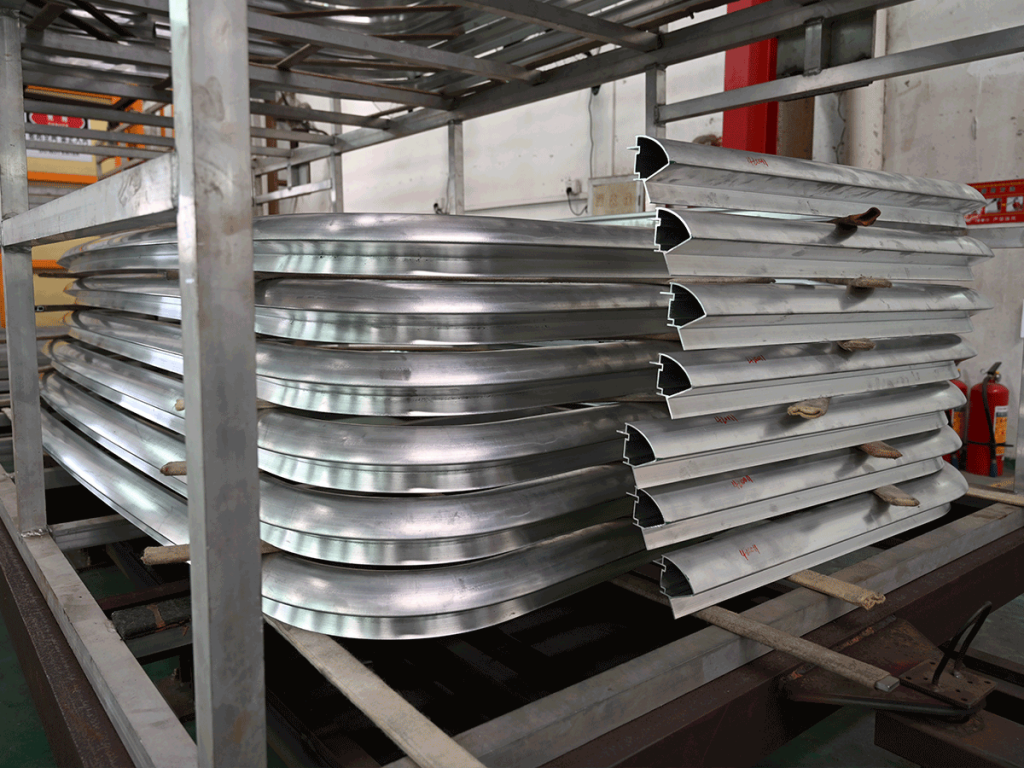

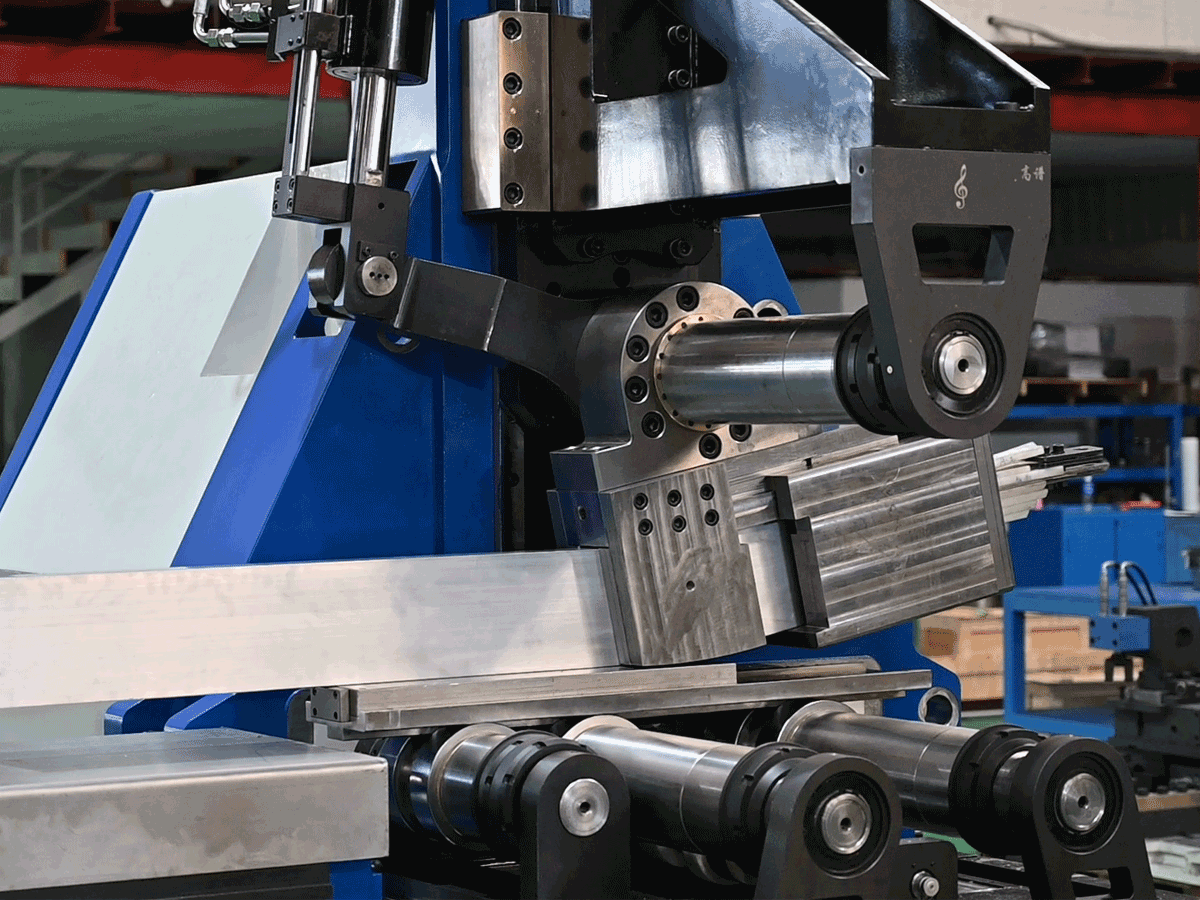

The G Clef on-line radius measuring device for roll bending is a real-time radius measuring device recently designed by G Clef, which has many significant advantages. It can measure the radius in real time during the roll bending process to ensure the accuracy of profile bending, greatly improving production precision and avoiding human errors that may occur in traditional manual measurement. At the same time, on-line measurement does not require shutdown, which can save production time and quickly feed back measurement results to the control system for timely adjustment of processing parameters. This device can also reduce the rejection rate, optimize processing parameters to reduce costs and extend the service life of toolings.

The on-line radius measuring device ensures the consistency of the radius of bent workpieces, improves the stability of product quality, meets the quality standards of products with high-precision requirements, and can record measurement data for convenient quality analysis and traceability. Welcome everyone to come for consultation!

Leave A Comment