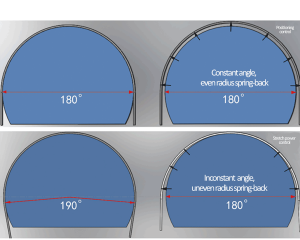

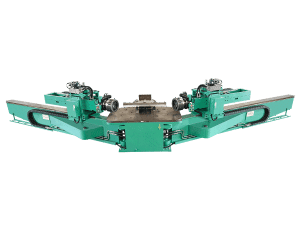

The structural design of rail vehicles must take into account multiple factors such as structure, aerodynamics, and aesthetics. Therefore, profiles are generally used in a bent state. However, the profile bending forming process is very complex and difficult to master. As a result, many defects such as wrinkling, cross-sectional shape distortion, and low contour shape accuracy are prone to occur during the bending and processing with traditional stretch bending machines and hydraulic profile bending machines, making it difficult to meet the manufacturing accuracy requirements of the vehicle body.

G Clef’s variable curvature CNC profile roll bending machine and CNC stretch bending machine with multiple core technologies can achieve a fully numerical control, high stability, and high-efficiency production mode, completely solving the problems of traditional profile bending machine tools being affected by material rebound and affecting processing accuracy, as well as relying on workers’ bending processing technology and experience.

Core Competence

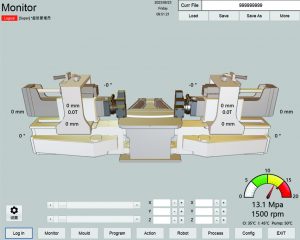

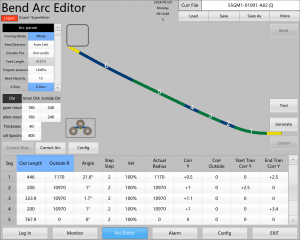

All adopts CNC

The advanced self-learning CNC system can automatically generate tooling parameters and operation programs without the need for human thinking.

Easy operation

The human-machine dialogue is concise. The system operation is simple and easy to learn. No skilled experience is required. Even novices can complete production step by step.

Neutral layer control

The equipment has stable performance. The repeat positioning accuracy can reach 0.01mm, ensuring product consistency.

Leave A Comment