In the aerospace field, bent pipes with complex spatial shapes serve as arteries or lifelines and are of great significance for ensuring the efficient operation of key equipment.

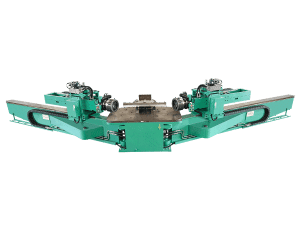

Through the efforts of G Clef’s R & D team, intelligent bending equipment that can make workpieces form accurately and efficiently has been successfully developed and produced, completely solving problems such as low production efficiency, excessive reliance on the experience of operators, and limitations of profile thickness and cross-sectional shape in traditional bending forming processes.

Core Competence

Independent core algorithm

The equipment can adapt to objective factors such as profile thickness, cross-sectional shape, operators, and temperature, and stably produce to create continuous value for users.

Complete tool accessories

Automatically generate tooling contours. Users can design, manufacture and maintain by themselves. No need to repair the tooling. Adjusting the rebound can be done by modifying the numbers.

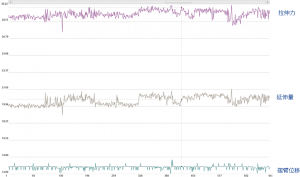

Material data acquisition

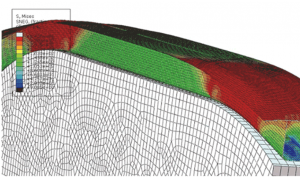

Real-time detection and collection of data such as material size and yield value, and automatic adjustment of parameters effectively solve problems such as distortion of material cross-section, web instability and springback.

-300x225.jpg)

Leave A Comment