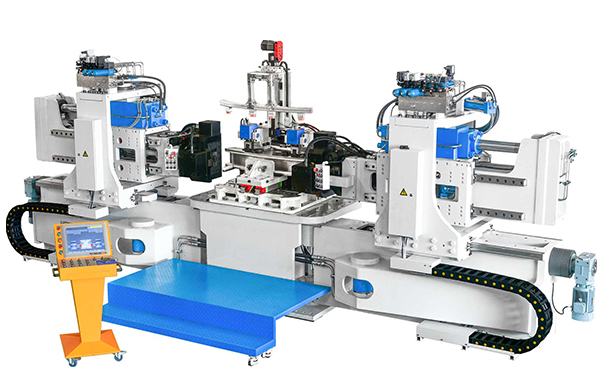

The advantages of Stretch Forming Machine for G Clef’s car bumper uses our own numerical control system. It become an automatic Stretch forming production system while it work with robot.And it can continuously produce accurate, standardized, unified car bumper and other parts day and night.

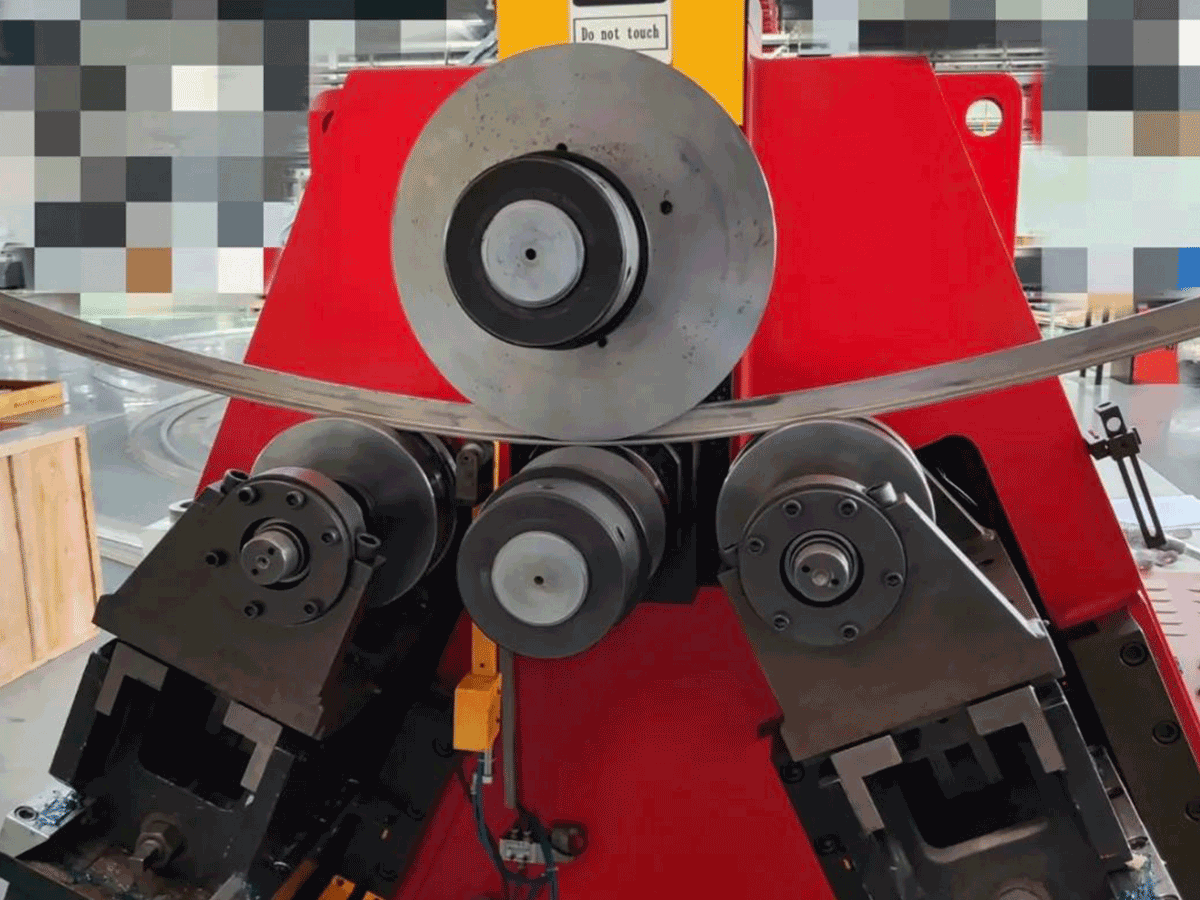

push and pull bending machine

The advantages of Stretch Forming Machine is mainly depends on our company’s NUMERICAL control system,It has the following advantages:

1, Beyond 16-axis servo control, stretch force and displacement are accurate.

2, Force mode or displacement mode are available in bending.

3, Automatic detection of profile yield strength, and stretch force adjusting accordingly.

4, Self-study CNC program, automatic molding parameter generation.

5, Stable bending quality and consistent bending accuracy.

6, Independent of skilled operator.

7, Energy-saving and green solution is provided to solve the hydraulic system’s heating problem.

Our Car Bumper Stretch Forming Machine is designed for the characteristics of the car bumper, with large tensile force, can bend the high-strength metal over 1000Mpa ;

This stretch forming machine applies complex scientific theory,

Such as neutral layer control technology, rebound control technology and so on!

However, through the efforts of our engineering team, the machine is simple and reliable, and can be repaired and maintained independently.

You can operate without professional basic knowledge;

Finally, we can provide two different testing tools: dedicated manual testing tools, or universal digital testing tools.

Among them, the digital detection tool is to compare the contour with the original design document by scanning.

It can directly output the detection results, more convenient to share and storage the results.

We are committed to studying bending technology, sincere service for customers,

To provide customers with the most appropriate bending solutions,

Such as roll bending machine, stretch froming machine, tube bender, and so on.

Leave A Comment