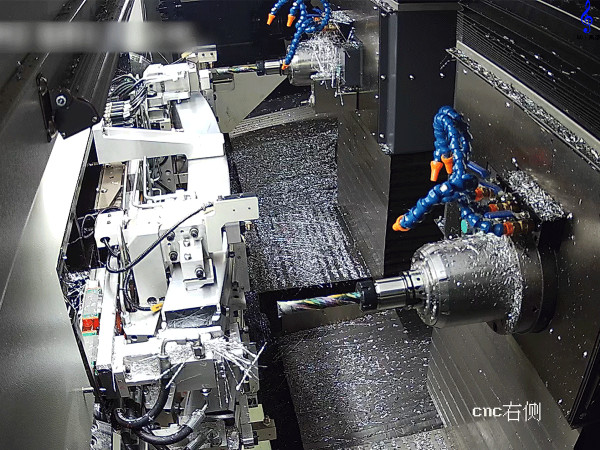

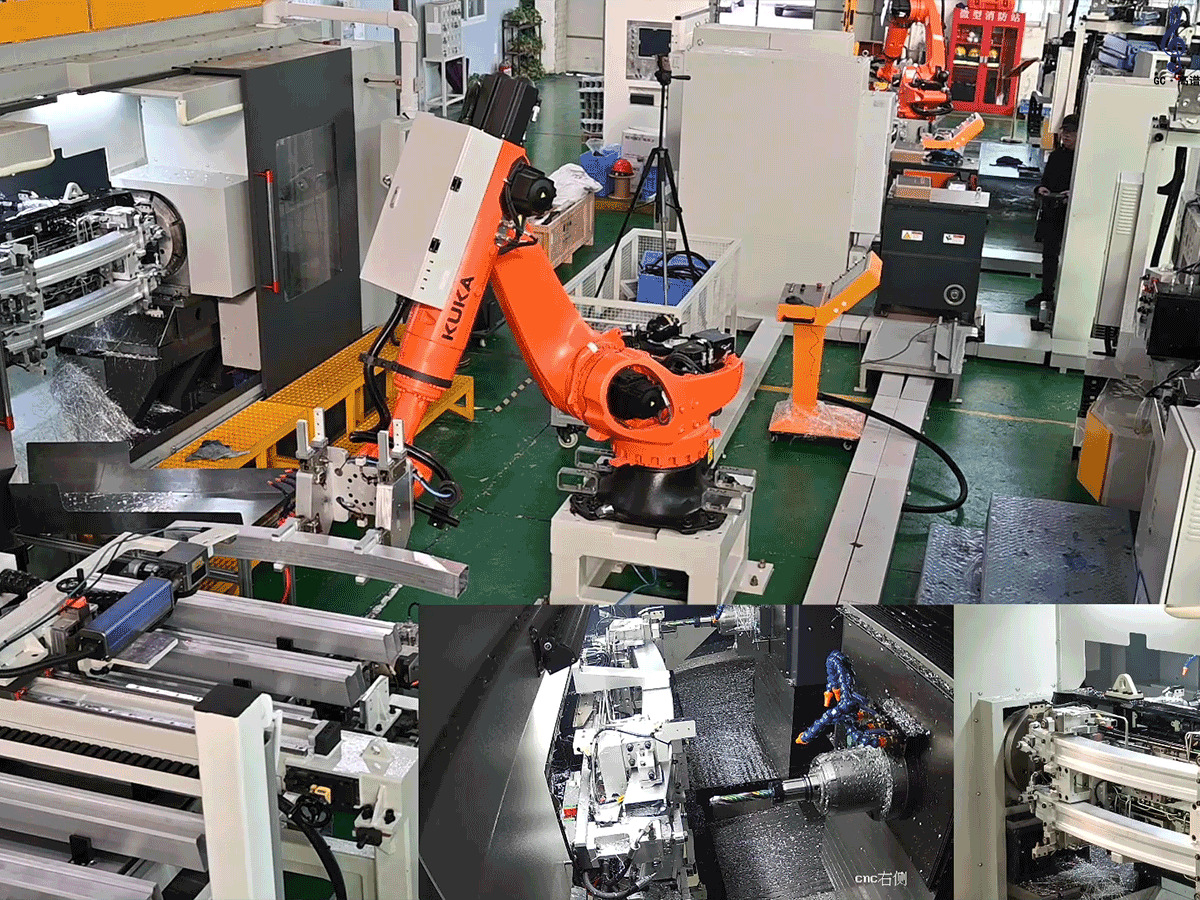

1. Dual – drilling CNC collaborative processing doubles the efficiency

The dual – head design is a major highlight of this workstation. With two independent CNC processing heads, different machining operations can be carried out simultaneously, doubling the processing efficiency.

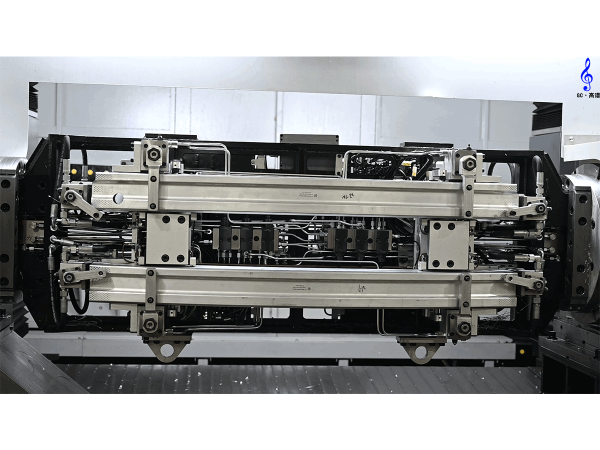

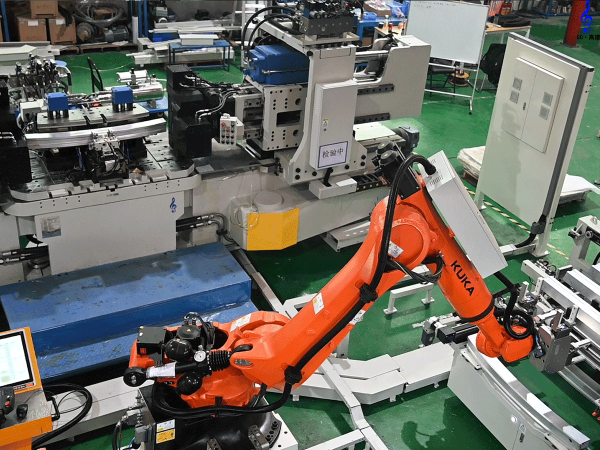

2.With fully automated production, product quality can be guaranteed

From automatic material feeding to finished product output, the entire process requires no human intervention. This reduces errors caused by human factors and further improves product quality.

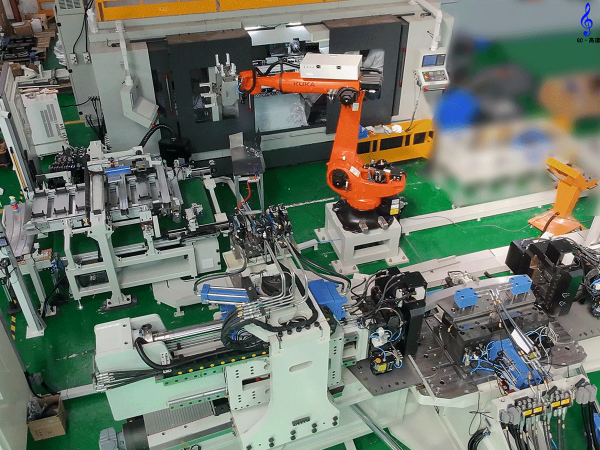

3.The combination of stretch – bending and CNC reduces errors

Completing stretch – bending and CNC machining within the same workstation avoids the time loss and positioning errors caused by transporting workpieces between different devices, ensuring the continuity and accuracy of processing.

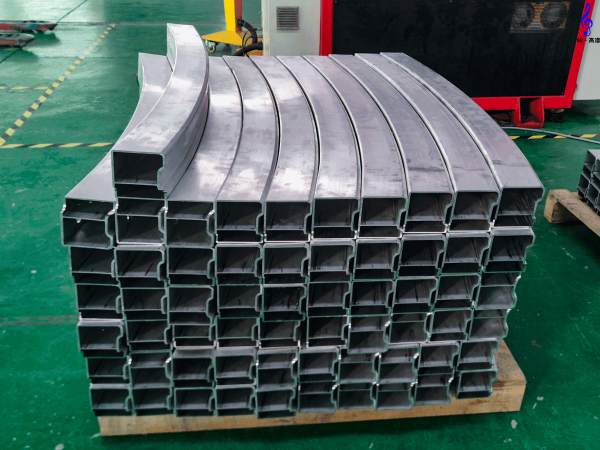

Application fields

- Automobile manufacturing: It can efficiently meet the processing requirements for complex – structured parts such as automotive anti – collision beams and bumpers.

- High – end equipment: It can meet the high – precision and high – standard requirements for complex – curved surface components in the aerospace industry.

- Rail transportation:it is applicable to the high – precision bending and intricate processing of components like body structural parts and handrails.

Leave A Comment