The most commonly used aluminum profiles in door and window processing are thermal break aluminum alloy profiles. They possess such advantages as being lightweight, having high strength, excellent water and air tightness, good fire resistance, large lighting areas, strong resistance to atmospheric corrosion, long service life, good decorative effects and excellent environmental protection performance. However, due to their complex cross-sectional shapes, wrinkles are prone to occur during cold bending processing, which affects the aesthetics of doors and windows

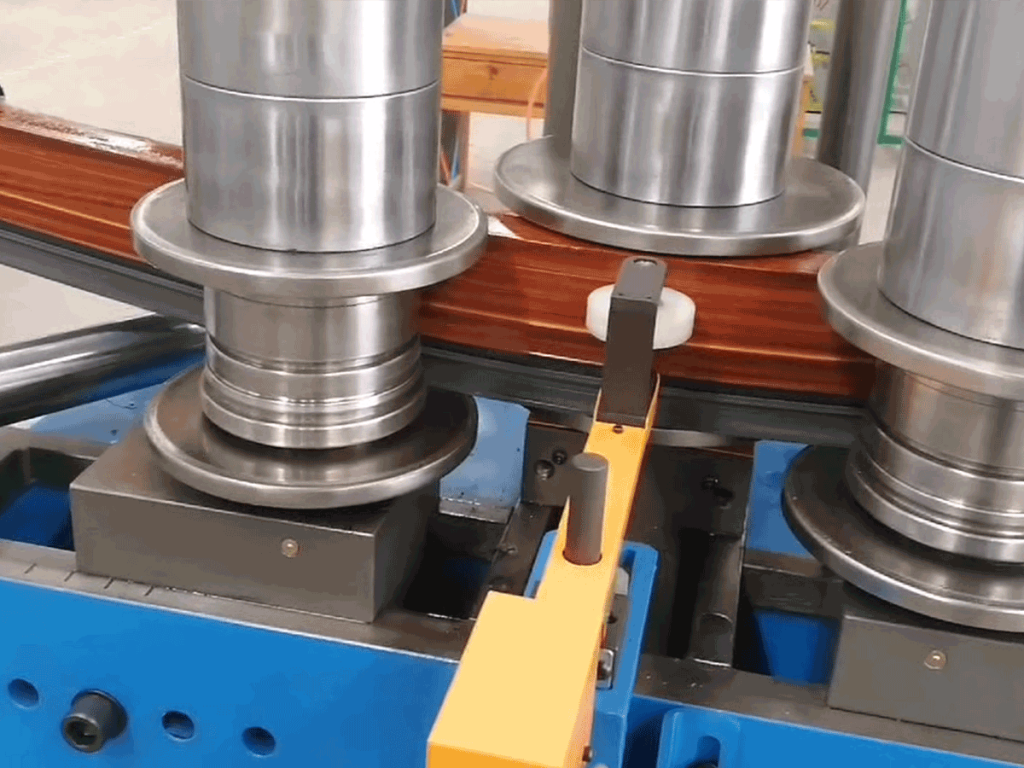

G Clef has successfully developed a numerically controlled variable-curvature roll bending machine. It has a unique core algorithm and abundant roll bending processing parameters. After importing CAD drawings, it can automatically generate processing trajectories and adjust the pressure automatically. It completely solves the quality problems that are prone to occur during the cold bending processing of aluminum profiles, such as wrinkling, scratching, twisting, indentation and unevenness, and meets customers’ requirements for high product quality

Core strengths

Strong applicability

The equipment is applicable not only to the common thermal break aluminum profiles for doors and windows, but also capable of bending metal profiles of different specifications and cross-sections.

Stable and durable

The equipment adopts high-quality materials and advanced manufacturing processes, and it can maintain stable working performance during long-term use.

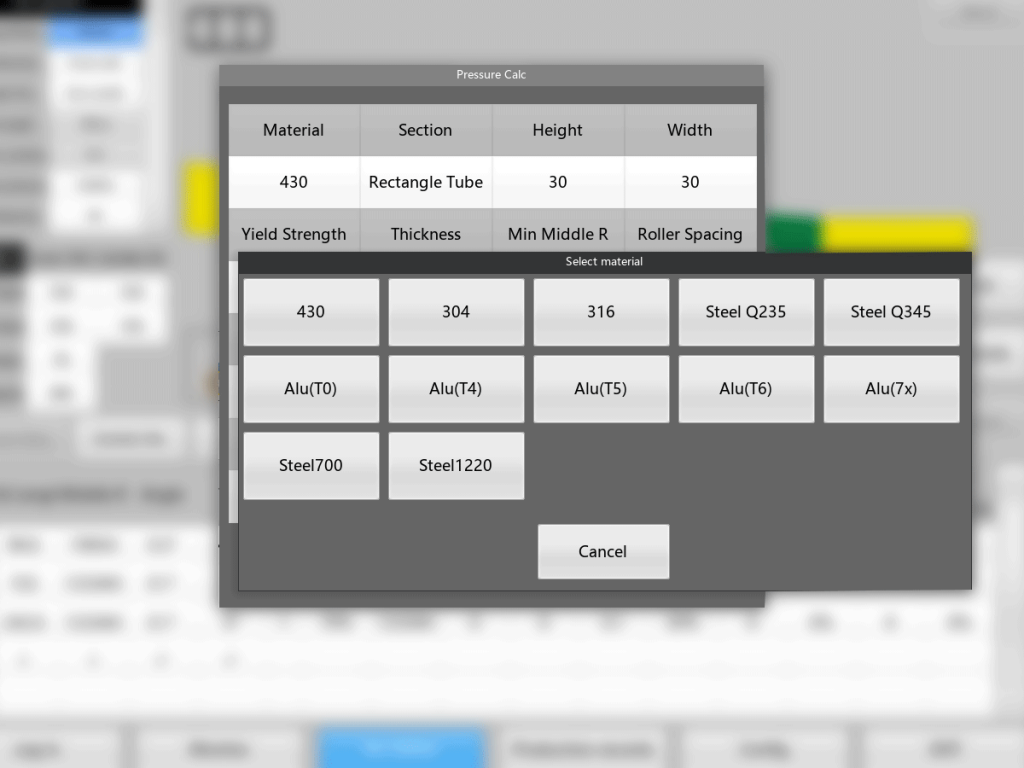

User-friendly operation

It adopts a simple and intuitive human-machine interface that is easy to understand at first glance and quick to learn.

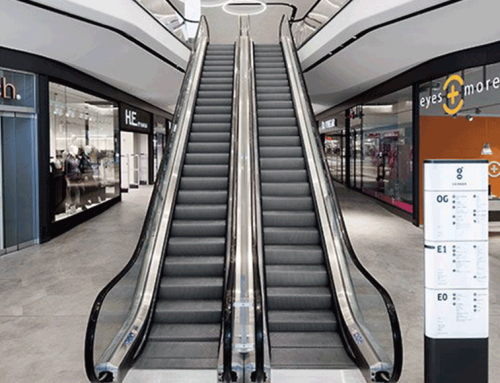

Cases

thermal break aluminum doors and windows

170mm radius

arc with small radius

Leave A Comment