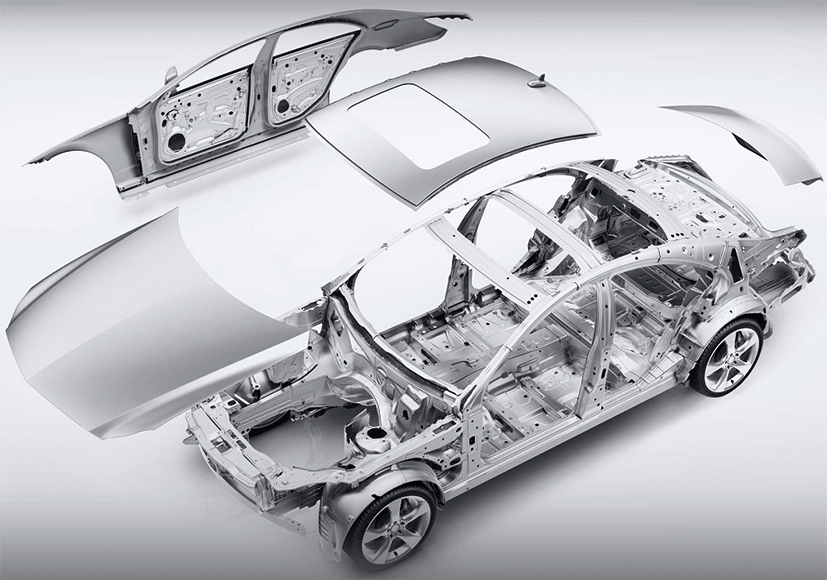

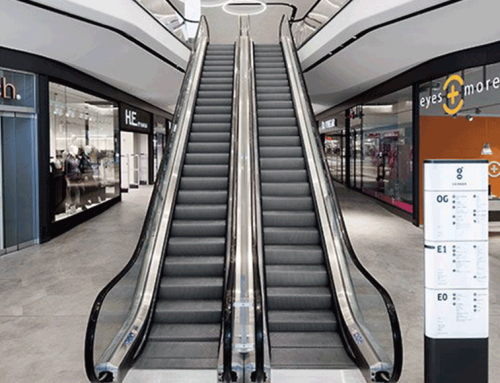

When designing the structure of automobiles, factors such as aerodynamics, aesthetics, safety and stability must be taken into account. Therefore, enterprises have high requirements for high precision and high stability of automobile curved parts. However, traditional bending equipment is prone to problems such as wrinkles, depressions, springback and deformation during the bending process. Production is overly dependent on manual experience and cannot achieve efficient and accurate processing, which reduces the efficiency of the entire production process.

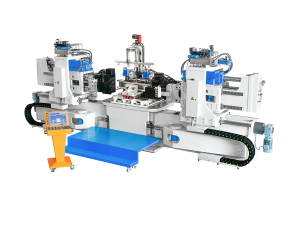

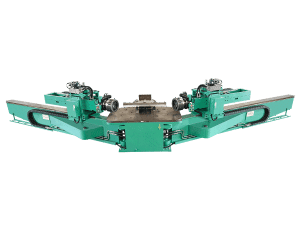

In response to the existing profile bending problems, G Clef has successfully developed a new generation of products such as variable curvature CNC roll bending machines, CNC stretch bending machines, and profile bending machines with completely independent core technologies and intellectual property rights. These products have the advantages of high working reliability, high production efficiency, high processing accuracy, and low operation and maintenance costs, and can provide professional bending solutions for automobile enterprises.

Core Competence

High stability

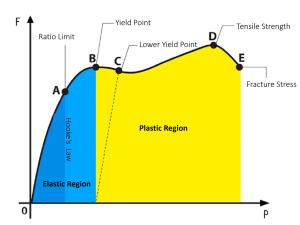

Adopting G Clef’s independent core algorithm, it automatically detects the yield strength of materials, effectively eliminates the internal stress of materials, and solves the problem that material springback affects the stability and precision of processed parts.

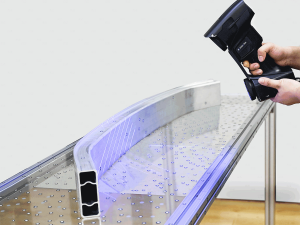

High accuracy

Adopting an intelligent CNC control system, it accurately and controls the tensile force and displacement in real time. The position accuracy is ≤±0.03mm, enabling the workpiece to be precisely bent and formed.

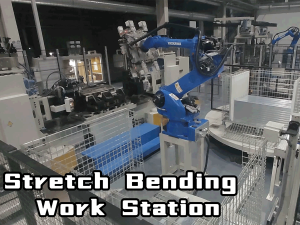

High efficiency

It has full automation production capacity. The production of one workpiece can be completed in 35-55 seconds, and the qualification rate reaches 99%.

Cases

Automobile bumper beam

Leave A Comment